Data is indeed the biggest missed opportunity in business today. A firm’s data can well be utilized for getting the insights to enhance. Using the data for the business intelligence showcases you what’s happening currently and the happenings in the past that may have led you or your company here.

BI gathers and analyzes several kinds of historical data for the strategic planning across the business, from the revenue growth and the customer experience to the development of the product or the way the company operates and functions.

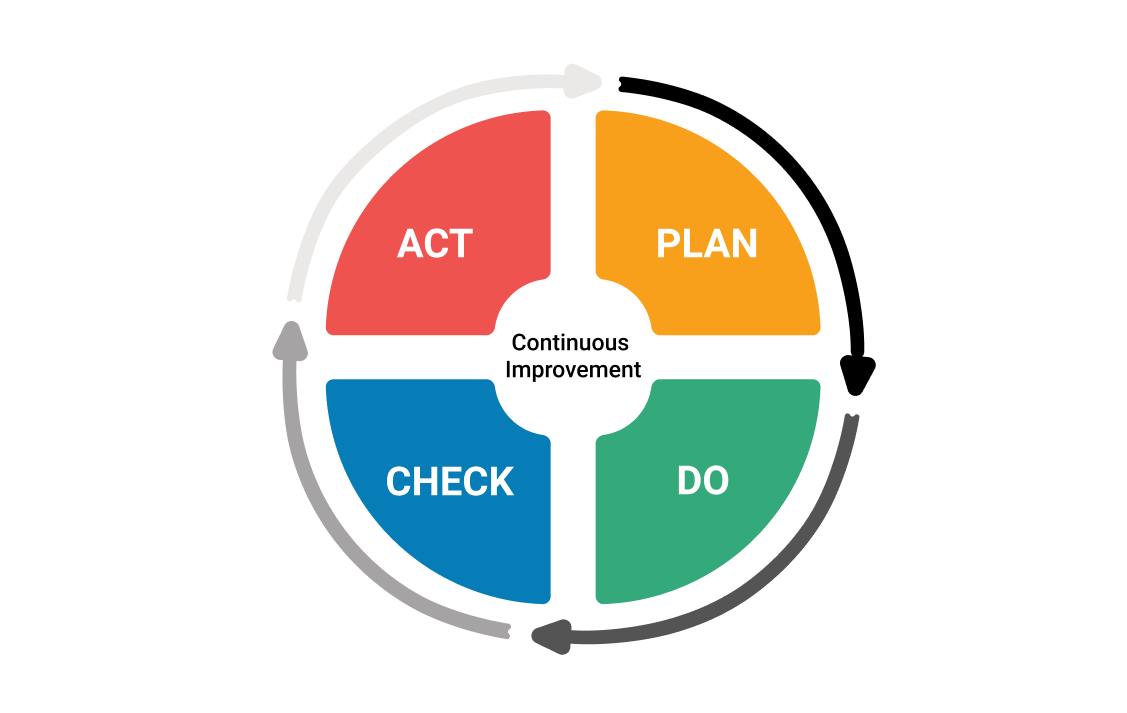

Operational intelligence is the essential facet of the BI that’s business intelligence that concentrates on the latter. It’s about analyzing the external and internal factors such as vendor management, employee workflows, and the software systems that both heavily rely on to learn how do they make the processes more and more efficient. That said, let’s now take a look at Continuous improvement.

What’s Continuous improvement in regards to Manufacturing?

It involves taking the established and stable production process and then looking for numerous ways to enhance it incrementally. It’s seen that although individual differences may not appear to have any major impact, the total would imply a major change and development to the manufacturing process as a whole.

By taking a tad bit incremental, calculative, and measured steps, the Manufacturers, as an everyday course of action, may ensure process enhancement while eradicating the very risk of making a massive leap to go and trying to achieve the same impact. The end objective of the continuous improvement in terms of Manufacturing is to have an effective production, with no waste, unscheduled disturbance, and unnecessary action. It’ll finally result in having optimal standardization.

Putting the data together lets to predict the trends and issues. One most popular way to go on and present analytics is via dashboards.

- The Operational dashboard: It’s made to be checked numerous times over the day to monitor processes subject to some of the frequent changes and track the outcomes of the metrics and the KPIs.

- The Strategic dashboard: It’s generally used via higher levels in organizations (executives or directors). Its major purpose is to go and monitor the very status of the key performance indicator.

- The Analytical dashboard: This usually requires data analysts’ development and design and is usually presented via advanced Business Intelligence features. It’s mainly utilized to analyze a huge amount of the data, predict outcomes, and investigate trends.

The firms use dashboards to showcase production kpi and read the complex analysis more easily. All the data Are extremely worth it for the businesses. It goes on to push towards the culture of continuous enhancement. Even smaller improvements month after month add up with time and go on to contribute to a profit.

Advantages

The advantages of using the dashboards are:

- Create a continuous culture of improvement

- Transparency of the data throughout a firm

- Making decisions and in control by having the correct data

- Better communication

To know more, you may do your research and look over the we